Our approach brings together cutting-edge technology and precision-controlled factory conditions. Not only does this ensure that our buildings meet the highest quality standards, it’s also safer for our workers, healthier for surrounding communities and has a far lower environmental impact.

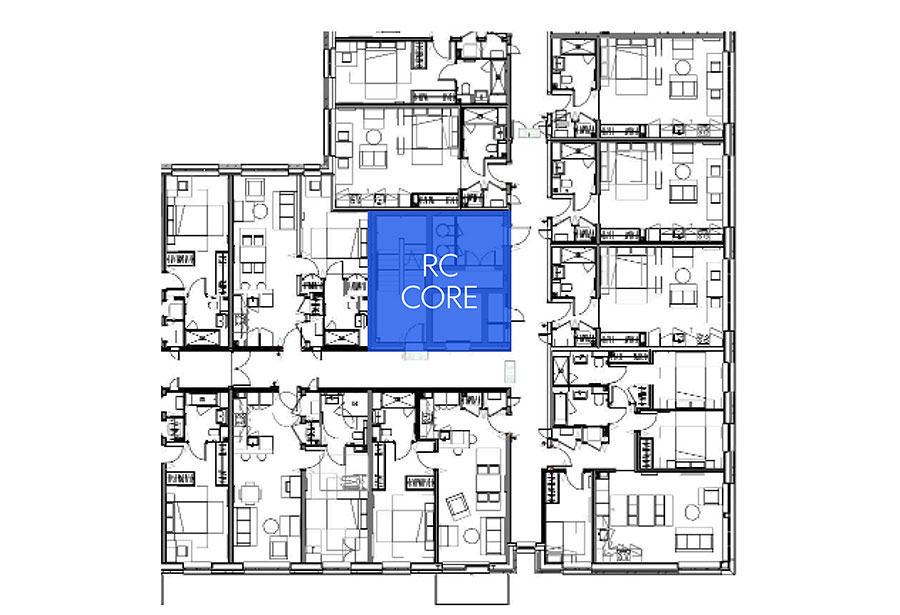

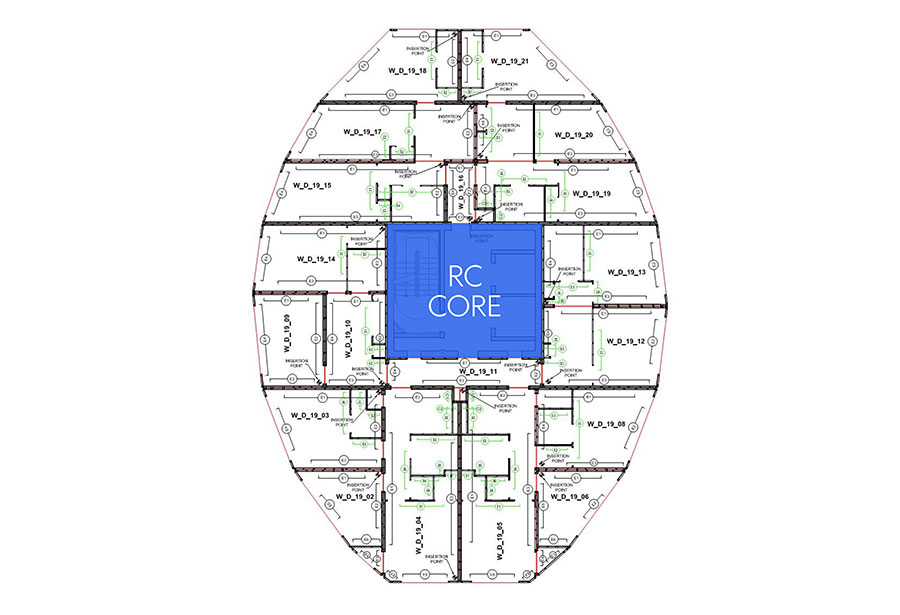

It starts with design. Our volumetric system has the flexibility to embrace and adapt to architects’ visions, and can manufacture complex shapes and massing with pinpoint accuracy. Throughout projects, our focus on quality remains relentless: we can trace every component from design through to operation.

Our buildings are the result of many years’ of research and testing. This has enabled us to build more efficiently, more sustainably, faster – and higher than ever before.

Our volumetric techniques produce architecture of the highest quality. We can adapt the system to deliver our clients’ existing designs and execute meticulous detailing in a variety of forms and materials.

We are trusted to deliver large-scale developments with lower maintenance costs and minimal defects. It’s precisely because of this foundation of trust that we are able to improve and refine our system’s performance in areas such as efficiency, height, sustainability, acoustics and fire safety.

Tide’s impressively fast volumetric building methods will soon deliver a much needed supply of high-quality rental accommodation across all levels of affordability with remarkable efficiency.

We are proud to be leading the transition to a safer, more sustainable construction industry. Up to 80% of a Tide building can be manufactured in the factory, drastically reducing high-risk site work. Our projects are inherently low carbon in construction, with significantly less material waste and far fewer deliveries to site.

Find out more about our related work, awards and events – and read our expert insights on the volumetric future.